Australia

August 14, 2018

Cotton shirts that you don't need to iron may sound like a fanciful dream, but could be a reality thanks to a new project being undertaken by CSIRO, Australia's national science agency.

A team of CSIRO scientists has started working on a cotton with many of the properties of synthetics, such as being stretchy, non-creasing and even waterproof, while retaining its natural fibre feel.

But before you throw away your iron, the team is first working on better understanding what determines the length, strength, and thickness of cotton fibres.

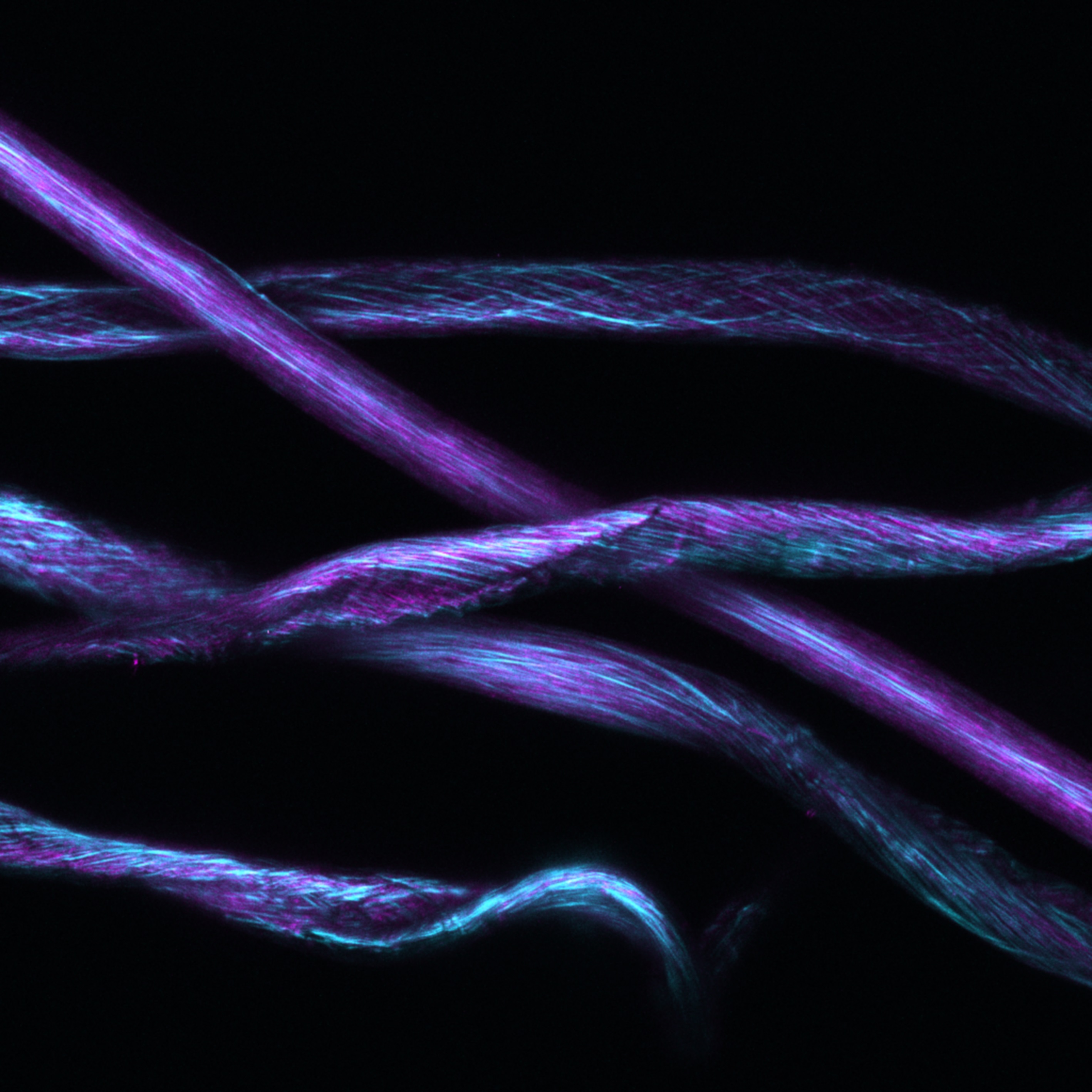

"We're looking into the structure of cotton cell walls and harnessing the latest tools in synthetic biology to develop the next generation cotton fibre," CSIRO scientist Dr Madeline Mitchell said.

"We've got a whole bunch of different cotton plants growing; some with really long thin fibres, others like the one we call 'Shaun the Sheep', with short, woolly fibres." Their work will be on display in Melbourne this week at AgCatalyst, a showcase of CSIRO's technologies across the agriculture and food sectors.

"Cotton often gets a bad rap environmentally but it is a natural, renewable fibre unlike synthetics which are made with petrochemicals," Dr Mitchell said.

Every time you wash synthetics like polyester and nylon, thousands of tiny microfibres of material are pulled free and enter our waterways.

These are not degradable and can build up in the food chain.

When you wash cotton, fibres are also shed but these are biodegradable and break down naturally in the environment.

Through more than 30 years of improved cotton breeding using GM techniques, CSIRO and partners, Cotton Seed Distributors (CSD), is credited with reducing insecticide use in cotton growing by 85 per cent and cutting herbicide use by 60 per cent. Australian cotton is also the most water efficient in the world.

"Australia produces three times more cotton per drop of water than any other country," Dr Mitchell said.

As well as environmental reasons, there is a strong commercial imperative for improving the versatility of cotton.

"If we can produce next generation cotton then we can take a large market share of the synthetics industry and that's a win not just for Australia's $2.5 billion industry but also for the environment," Managing Director of CSD Peter Graham said.

"Australian cotton has a reputation for being one of the best in the world.

"We need to stay ahead of our competitors, both in cotton but also synthetics."

In 1995 synthetics constituted about half of the global fibre market and by 2015 it had risen to 77 per cent. The overall growth in the size of the fibre industry means that while the cotton market hadn't shrunk, it also hadn't increased a significant amount.

"Synthetics may be cheaper to produce and require less ironing but people like natural fibres - they would just prefer they didn't crease so much or they could stretch," Dr Mitchell said.

The next generation cotton research is part of CSIRO's Synthetic Biology Future Science Platform, a $13 million investment in science that applies engineering principles to biology.

SynBio projects aim to provide societal benefits and opportunities for a wide range of industries.

Cotton fast facts

- The word 'cotton' comes from the Arabic 'qutun' or 'kutun', which describes any fine textile.

- Cultivated cotton first arrived in Australia with the First Fleet but it wasn't until the 1960s that our cotton industry really began to take off.

- 14 per cent of the world's cotton goes into producing denim jeans.

- In Australia there are just over 1,200 cotton farms across the country.

- In an average year, Australia's cotton growers produce enough cotton to clothe 500 million people.

- Australia has the highest yielding cotton in the world, that is, the most lint per hectare.

- Australia exports $2.7 billion worth of raw cotton each year.

- Cotton fruit are known as bolls. Inside each boll is the fluffy white lint we know as cotton as well as cotton seeds.

- Cotton seed is used in cattle feed or crushed to produce an oil for cooking, soap, margarine, and cosmetics.

- Short fibres that remain on the seed after ginning are used in bandages, cotton buds and even bank notes.

- Each cotton fibre is a single cell; one of the longest known plant cells at a whopping 3cm+ long. You can see it without a microscope!

- CSIRO-bred cotton varieties have increased productivity in Australia by more than $5 billion.

Half the dryland cotton in the United States and about one-third of the cotton in Brazil, Turkey and Greece, also benefits from CSIRO-bred varieties.